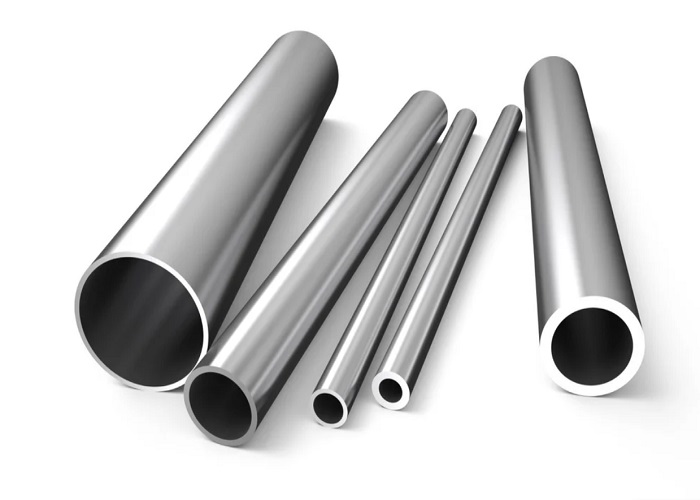

Titanium tubes come in various forms, including seamless, welded, and extruded. They are further classified based on their shape, such as round, square, and rectangular, offering versatility for diverse applications.

Seamless Titanium Pipes

Seamless titanium pipes are manufactured without any welding seams, resulting in a uniform structure that enhances strength and corrosion resistance. These pipes are renowned for their high precision, making them ideal for critical applications such as aerospace components, chemical processing, and medical implants.

Welded Titanium Pipes

Welded titanium pipes are fabricated by welding together titanium sheets or strips, offering a cost-effective alternative without compromising quality.

Both seamless and welded titanium pipes adhere to rigorous specifications, including ASTM standards, ensuring consistent quality and performance. With their impressive strength-to-weight ratios, excellent corrosion resistance, and versatility in size and configuration, seamless and welded titanium pipes are indispensable components in numerous industries, driving innovation and progress worldwide.

We pride ourselves on offering top-quality titanium tubes and pipes, meeting stringent industry standards. With our diverse range of forms and specifications, we provide tailor-made solutions to suit your specific needs, ensuring success in every project.

Pipe Type: Customized seamless tubes and welded tubes

Material: Gr1, Gr2, Gr5, Gr7, Gr9, Gr11, Gr12, Gr18, Gr23, etc.

Standards: GB, ASTM, ASME, AMS, MIL, JIS, DIN.

Applications: Tailored for diverse industries including aerospace, medical implants, chemical processing, and marine structures.

Customization Options: Available in various diameters (6mm to 150mm) and wall thicknesses (1mm to 4.5mm) to meet unique project requirements.

Welcome to contact us for more customized solutions.

Aerospace and Aviation

Aircraft Airframes

Engine Components

Hydraulic Systems

Medical

Orthopedic Implants

Surgical Instruments

Dental Implants

المعالجة الكيميائية

Titanium Heat Exchangers

Reactor Vessels

Pipelines

Marine

Ship Hulls

Submarine Structures

Offshore Oil and Gas Platforms

Automotive

Exhaust Systems

Racing Car Frames

Turbocharger Components

Power Generation

Gas Turbine Components

Heat Transfer Tubing

Nuclear Reactor Systems

Titanium Tubes Grade for your choice!

الصف 1

is the most ductile and softest titanium alloy. It is a good solution for cold forming and corrosive environments. ASTM/ASME SB-265 provides the standards for commercially pure titanium sheet and plate.

Grade 2

Unalloyed titanium, standard oxygen.

Grade 2H

Unalloyed titanium (Grade 2 with 58ksi minimum UTS).

الصف 3

Unalloyed titanium, medium oxygen.

Grades 1-4 are unalloyed and considered commercially pure or "CP". Generally the tensile and yield strength goes up with grade number for these "pure" grades. The difference in their physical properties is primarily due to the quantity of interstitial elements. They are used for corrosion resistance applications where cost, ease of fabrication, and welding are important.

Grade 5 also known as Ti6Al4V, Ti-6Al-4V or Ti 6-4

درجه 6

contains 5% aluminium and 2.5% tin. It is also known as Ti-5Al-2.5Sn. This alloy is used in airframes and jet engines due to its good weldability, stability and strength at elevated temperatures.

الصف 7

contains 0.12 to 0.25% palladium. This grade is similar to Grade 2. The small quantity of palladium added gives it enhanced crevice corrosion resistance at low temperatures and high pH.

Grade 7H

is identical to Grade 7 (Grade 7 with 58ksi minimum UTS).

الصف 9

contains 3.0% aluminium and 2.5% vanadium. This grade is a compromise between the ease of welding and manufacturing of the "pure" grades and the high strength of Grade 5. It is commonly used in aircraft tubing for hydraulics and in athletic equipment.

الصف 11

contains 0.12 to 0.25% palladium. This grade has enhanced corrosion resistance.

Grade 12

contains 0.3% molybdenum and 0.8% nickel. This alloy has excellent weldability.

Grades 13, 14, and 15

all contain 0.5% nickel and 0.05% ruthenium.

Grade 16

contains 0.04 to 0.08% palladium. This grade has enhanced corrosion resistance.

Grade 16H

is identical to Grade 16 (Grade 16 with 58 ksi minimum UTS).

Grade 17

contains 0.04 to 0.08% palladium. This grade has enhanced corrosion resistance.

Grade 18

contains 3% aluminium, 2.5% vanadium and 0.04 to 0.08% palladium. This grade is identical to Grade 9 in terms of mechanical characteristics. The added palladium gives it increased corrosion resistance.

Grade 19

contains 3% aluminium, 8% vanadium, 6% chromium, 4% zirconium, and 4% molybdenum.

Grade 20

contains 3% aluminium, 8% vanadium, 6% chromium, 4% zirconium, 4% molybdenum and 0.04% to 0.08% palladium.

Grade 21

contains 15% molybdenum, 3% aluminium, 2.7% niobium, and 0.25% silicon.

Grade 23 also known as Ti-6Al-4V-ELI or TAV-ELI

Grade 24

contains 6% aluminium, 4% vanadium and 0.04% to 0.08% palladium.

Grade 25

contains 6% aluminium, 4% vanadium and 0.3% to 0.8% nickel and 0.04% to 0.08% palladium.

Grades 26, 26H, and 27

A hexagon formed from thermal stir welding of a Titanium alloy

all contain 0.08 to 0.14% ruthenium.

Grade 28

contains 3% aluminium, 2.5% vanadium and 0.08 to 0.14% ruthenium.

Grade 29

contains 6% aluminium, 4% vanadium and 0.08 to 0.14% ruthenium.

Grades 30 and 31

contain 0.3% cobalt and 0.05% palladium.

Grade 32

contains 5% aluminium, 1% tin, 1% zirconium, 1% vanadium, and 0.8% molybdenum.

Grades 33 and 34

contain 0.4% nickel, 0.015% palladium, 0.025% ruthenium, and 0.15% chromium. Both grades are identical but for minor difference in oxygen and nitrogen content.[30] These grades contain 6 to 25 times less palladium than Grade 7 and are thus less costly, but offer similar corrosion performance thanks to the added ruthenium.

Grade 35

contains 4.5% aluminium, 2% molybdenum, 1.6% vanadium, 0.5% iron, and 0.3% silicon.

Grade 36

contains 45% niobium.

Grade 37

contains 1.5% aluminium.

Grade 38

contains 4% aluminium, 2.5% vanadium, and 1.5% iron. This grade was developed in the 1990s for use as an armor plating. The iron reduces the amount of Vanadium needed as a beta stabilizer. Its mechanical properties are very similar to Grade 5, but has good cold workability similar to grade 9.